Make India Happen: Sourcing from India

A few compelling facts about manufacturing in India:

- Currently at $388 billion; on track to reach $1 trillion by 2025

- Parts/components and industrial machinery exports have increased by 55% in the last 5 years

- Auto-components industry will grow from $43.5 billion to $200 billion in revenue by 2026; and exports will expand from $11.2 billion to $100 billion by 2026

Developing a successful supply chain with India requires knowledge of Indian manufacturing, how business is conducted there, and knowing where and how to find suppliers with proven capabilities. Schedule a Consult

Scroll Down for MoreOur Process- and Data-Driven Approach

- Understand your need: A one-on-one sit down with the client to understand ‘Why India?’ What parts/components and/or engineering services are being considered for outsourcing? What are the commodity areas and manufacturing process capabilities of relevance and interest?

- Determine the Fit: A review of the client’s product portfolio and part/component requirements. Visthar helps select the right sourcing package to get started, based on commodity and complexity. Educating the client on what works in India and what doesn’t is key to success.

- Find the Right Supplier: Every customer demands specific attributes of a supplier. Visthar helps Identify, Qualify, Select, and Manage the best-suited supplier for each client. Criteria used to evaluate and select suppliers include Quality, Cost, Delivery, and intangibles such as supplier’s international business experience and company culture.

- Deploy in India: Visthar’s on-going supplier management activities — from RFQ to Production — include oversight of Sample Development, PPAP Approval, and Pre-production outputs. On-the-ground supplier audits are conducted as required, and regular monitoring and reporting to US customers is a part of Visthar’s quality process. Frequent interaction between Indian suppliers and US customers’ Engineering, Quality and Sourcing teams is a natural outcome of this approach.

- Deliver in the US: In collaboration with the client’s strategic sourcing, purchasing and quality personnel, Visthar continuously tracks supplier performance. Deliverables include quality monitoring (Root Cause Analysis, CAPA reporting, Project Management, etc.) supported by timely communications and relevant reports. Visthar also offers US-based logistics and warehousing support to its customers, as required.

We don’t just supply parts/components, we collaborate on best-fit solutions.

Our Experienced Supply Chain Partners in India

Visthar’s clients directly benefit from the knowledge gained and relationships built over 20+ years of doing business in India. Our team has developed a tried and tested network of manufacturers and sourcing partners across a variety of industries.

The Visthar team’s successful implementation of over 70 sourcing projects within the last 8 years has required a significant on-the-ground presence in India, thus growing our access to new partners across different commodities and capabilities, while also deepening our existing supplier relationships within key industries.

High-quality suppliers introduce us to other high-quality suppliers!

India’s inherent strengths in Engineering, Metallurgy, Rubber Technology, and other technical specialties add to Visthar’s suite of Strategic Souricng Services and enhances the value delivered to the client.

Visthar’s India supply capability is further strengthened by the company’s network of US-based consultants across the supply chain who help us optimize our clients’ sourcing spend.

It’s as much who you know, even more so in India.

Our Supplier Capabilities & Industry Focus

Supplier Capabilities

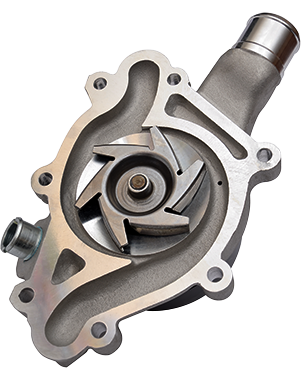

- Presicion Forging & Machining

- Metal Castings (Sand, Investment, HPDC, others)

- Metal Stampings

- Metal Injection Molding (MIM)

- Rubber (Molded & Extruded)

- Plastic (Molded & Extruded)

- Rubber-to-Metal (Bonding & Overmolding)

Industries Served

- Lawn & Garden

- Outdoor Power Equipment

- Power Generation

- Agricultural & Construction

- Sports & Recreational Vehicles

- Off-Highway Equipment

- Oil & Gas

- Fluid Handling & Flow Measurement

We Select Suppliers to Match the Demands of the US Market.

What We Deliver

- Value Engineering approach working with client to optimize part design, raw material usage, best-suited mfg. process, DFM

- Client support by monitoring deliveries, managing lead times and finding ways to optimize variables within the supply chain

- Attention to ‘Quality’ – beyond the product – we practice Root-Cause Analysis, CAPA, and strive for Zero-defect

- Regular Communications from RFQ through part development into production; no hesitation to recognize, communicate and address mistakes

How Visthar Reduces Total Cost of Ownership

Working with Visthar and our India suppliers, there are NO additional/unforeseen costs.

This means NO Supplier Management costs, NO costs associated with our commitment to quality, NO on-the-ground overhead in India, NO additional risk for the customer.

What we quote is all you pay!

We Convert Your Sourcing Challenges Into Measurable Success in India.

Request Consult

A quick conversation and sharing of ideas will help determine next steps.